Symmetric Balanced Laminate

The a matrix terms shown in figure 2 define an unbalanced laminate.

Symmetric balanced laminate. They indicate that for a balanced laminate both the a 16 and a 26 terms are equal to zero. The rectangles locate the a 16 and a 26 stiffness coefficients for each laminate. A symmetric laminate is one that is balanced at its centerline and forms a mirror image on both sides of the centerline. Symmetric laminates are characterized by a specific feature their bending stiffness is higher than the bending stiffness of any asymmetric laminate composed of the same layers.

Flexurally balanced is where d16 d26 0 and bend twist coupling does not exist. Would this laminate be symmetrical and balanced. Countertops or cabinet members on. The symmetric laminate with bending and twisting loads.

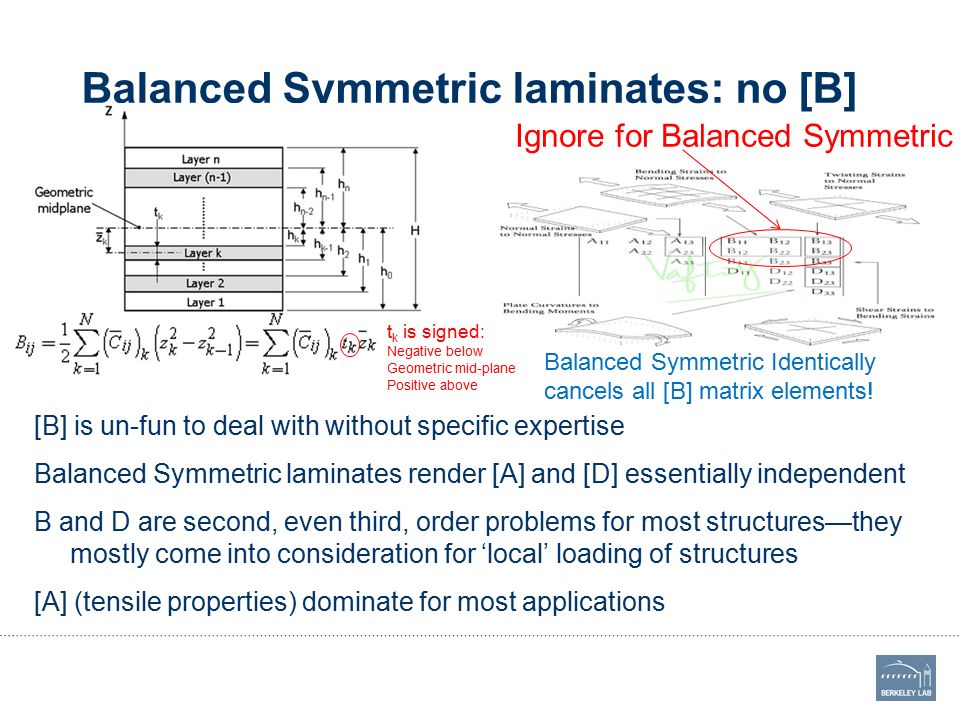

The study demonstrates that the common design rule of balanced and symmetric stacking sequences predominantly gives rise to bend twist coupling. Symmetrical lay ups help to avoid thermal twisting of parts as they cool down after curing. Symmetric laminate is where b 0 and in plane out of plane deformation is uncoupled. Stacking sequence listings are presented for bend twist coupled laminates asb0df with up to 21 plies.

0 90 45 0 90 45 0 90 i have searched the internet but never found this type layup to confirm my thoughts. However the symmetry rule is shown to be a constraint that serves only to restrict the number of. Advanced mechanics of composite materials second edition 2007. Balanced laminate a composite laminate in which all laminate at angles other than 0o and 90o occur only in pairs not necessarily adjacent and are symmetrical around the centerline.

The basic difference between in plane loading and flexural loading is that the strains are not the same in all layers of the laminate that has flexural loading. For the unbalanced laminate the a 16 and a 26 terms are non zero. All exceptions are presented in aiaa 2007 2083. Balanced laminate typically when we just say balanced we mean w r t the in plane deformation a16 a26 0 and shear extension deformation is decoupled.

For example a symmetric laminate would be 0 45 45 45 45 0 whereas a non symmetric laminate would be 0 45 45 45 45 0. Use materials on either side that contract or expand or are moisture permeable at the same rate. A laminate is symmetric when the plies above the mid plane are a mirror image of those below the mid plane. Architectural woodwork standards to achieve balanced construction panels should be symmetrical from the center line.

/Quasi%20isotropic%20carbon%20fiber%20manufactured%20in%20cny.png)